The Hidden World of Automotive Fluid Dynamics

Automotive engineering has long been associated with the visible and tangible aspects of vehicles - sleek bodywork, powerful engines, and cutting-edge interiors. However, beneath the surface lies a critical yet often overlooked field that plays a pivotal role in vehicle performance, efficiency, and safety: automotive fluid dynamics. This intricate science shapes the way vehicles interact with air, coolants, and lubricants, influencing everything from fuel economy to handling characteristics.

The Evolution of Automotive Fluid Dynamics

The roots of automotive fluid dynamics can be traced back to the early days of automotive engineering, when designers first began to consider the impact of air resistance on vehicle performance. However, it wasn’t until the mid-20th century that this field truly began to flourish. The advent of wind tunnels specifically designed for automotive testing marked a significant milestone, allowing engineers to visualize and measure airflow patterns around vehicles with unprecedented accuracy.

As computational power increased in the latter half of the 20th century, Computational Fluid Dynamics (CFD) emerged as a game-changing tool in automotive design. CFD simulations enabled engineers to model complex fluid interactions without the need for physical prototypes, dramatically accelerating the design process and allowing for more innovative solutions.

The Invisible Force: Airflow Management

One of the most critical applications of fluid dynamics in automotive design is the management of airflow around the vehicle’s exterior. At high speeds, air resistance becomes a significant factor in a vehicle’s performance and efficiency. Engineers employ various techniques to optimize a car’s aerodynamic profile, reducing drag and improving stability.

Subtle design elements, such as carefully sculpted side mirrors, integrated spoilers, and underbody panels, all play a role in directing airflow efficiently around the vehicle. These features not only enhance fuel economy but also contribute to vehicle stability, reducing lift and improving handling characteristics at high speeds.

Internal Flow: The Lifeblood of Performance

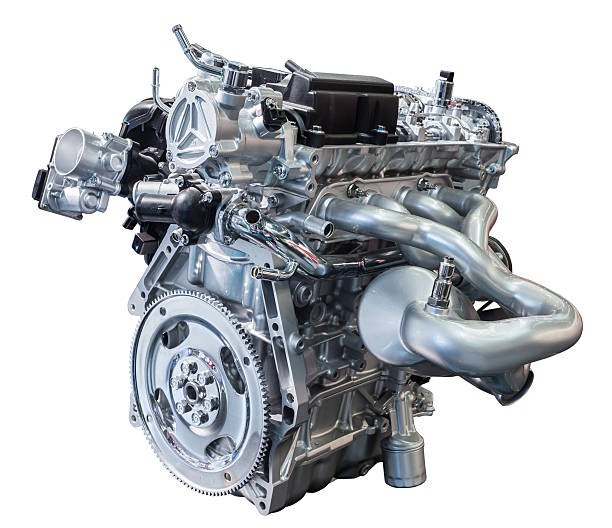

While external aerodynamics often steals the spotlight, the management of internal fluid flows is equally crucial to a vehicle’s performance and longevity. The intricate network of channels and passages within an engine block, for instance, must be carefully designed to ensure optimal circulation of coolant and oil.

Engineers use fluid dynamics principles to design intake and exhaust systems that maximize airflow efficiency, directly impacting engine performance. The shape and size of intake manifolds, the curvature of exhaust headers, and the design of mufflers all play a role in optimizing the flow of gases into and out of the engine.

Thermal Management: Keeping Cool Under Pressure

As vehicles become more powerful and compact, effective thermal management becomes increasingly challenging. Fluid dynamics plays a crucial role in designing cooling systems that can efficiently dissipate heat from high-performance engines and electric powertrains alike.

Advanced CFD simulations allow engineers to model the complex interactions between coolant flow, heat transfer, and component geometry. This enables the development of more efficient radiators, optimized coolant passages, and innovative thermal management solutions such as phase-change materials and microfluidic cooling systems.

The Future of Automotive Fluid Dynamics

As the automotive industry continues to evolve, the importance of fluid dynamics in vehicle design is only set to increase. Emerging technologies such as active aerodynamics, which allow vehicles to dynamically alter their aerodynamic properties in real-time, promise to revolutionize vehicle efficiency and performance.

Moreover, the shift towards electric and hydrogen-powered vehicles presents new challenges and opportunities in the field of automotive fluid dynamics. The unique cooling requirements of battery packs and fuel cells, coupled with the need for ultra-low drag coefficients to maximize range, are driving innovation in this space.

Advanced simulation techniques, including machine learning-enhanced CFD models, are enabling engineers to explore increasingly complex fluid dynamic interactions. These tools are paving the way for the next generation of vehicles that push the boundaries of efficiency, performance, and sustainability.

In conclusion, the hidden world of automotive fluid dynamics represents a fascinating intersection of physics, engineering, and computational science. As vehicles continue to evolve, this often-overlooked field will play an increasingly critical role in shaping the future of transportation. From enhancing performance and efficiency to enabling new powertrain technologies, the principles of fluid dynamics will remain at the heart of automotive innovation for years to come.